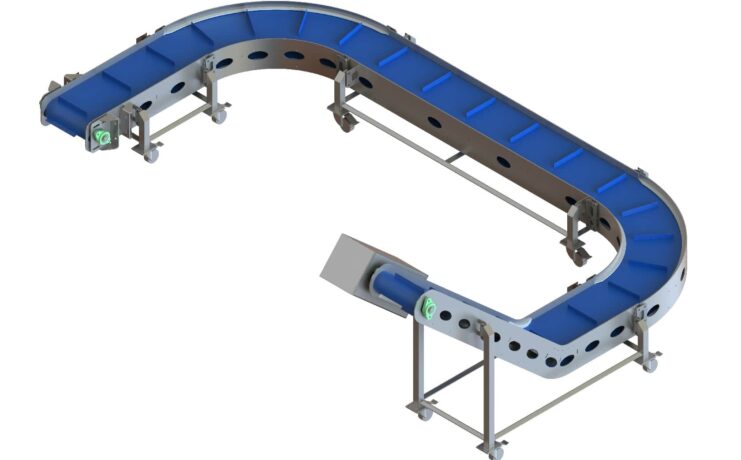

When speed and precision are crucial, choosing the right incline conveyor can help move things smoothly. Different types and configurations of vertically moving conveyors exist. Why is an incline conveyor suitable for you? There are several considerations. Read our comprehensive information before buying an inclination conveyor. It will help you choose wisely and ensure it satisfies all your demands.

Know Your Material:

The most important thing you can do when picking incline conveyors is to know exactly what it will be used for. Different materials are different in terms of their size, weight, and how rough they are. The rules for a conveyor that moves fragile food will be different from those for a conveyor that moves heavy building materials. The best type of belt, drive mechanism, and overall conveyor design for your needs will depend on the resources you have.

Finding the Angle of Inclination:

The angle of inclination is a key part of how an incline conveyor is built and how it works. It shows how well the conveyor can move things up and down. If the hill is steep, you may need special belts or extra support systems to keep things from falling or spilling. To find the right conveyor for your needs, you must know the angle at which the things you need to move are to be moved.

Figure Out Your Throughput Needs:

It’s very important to think about your throughput, or how much stuff needs to be moved per unit of time. The size, speed, and shape of the machine as a whole are all changed by it. You can choose a conveyor that can move the amount of stuff you need to move without slowing down if you know how much flow you need. What kind of output does the machine need to meet your production needs? Do you need a steady flow of material or short bursts of it?

Take a Look at Your Limited Space:

Your building only has so much room, and the way your business is set up will determine which type of incline conveyor will work best for you. You should think about how much floor room you have and any height limits. For example, inclined conveyors can be straight, Z-shaped, or round. They also come in different sizes and forms. If you choose a plan that makes the most of the space you have, the layout will be better and your business will run more smoothly.

Getting the Right Type of Belt:

An important part of getting an incline conveyor is getting the right type of belt. The type of material being moved, as well as its size and weight, will help you choose the right belt. Belts are often made of rubber, PVC, or materials that are reinforced with cloth. You might need special belts when moving things like food, rough things, or things that are going up steep hills. You can choose a belt that will last and make moving your things easier if you know what your materials need.

Taking a Look at Drive Mechanisms:

An incline conveyor’s ability to move items efficiently depends on its drive mechanism. Electric motors, gears, and pulley systems are all common types of drives. The type of drive device you choose should match the properties of the materials you’re using and the needs of your application. To make sure the drive mechanism is both reliable and flexible, think about things like motor power, speed control, and the need for extra-stopping systems.

Checking for Safety Features:

In any workplace setting, safety is a must, and incline conveyors should have strong safety features. Safety features like emergency stop buttons, guardrails, and sensor systems help keep people and equipment safe and avoid accidents. To make a safe place to work, you need to know about the safety features that are out there and decide if they will work with your needs.

Environmental and Hygiene Considerations:

If you work in a dirty industry like food processing or medicines, you need to make sure that the incline conveyor you choose is made of materials and has a design that meets industry standards. To meet strict cleanliness standards, buildings made of stainless steel and the ability to be washed down are often needed. For uses that care about the environment, choosing conveyors that use less energy or are made from materials that can be recycled is also in line with sustainable practices.

Making Incline Conveyors Fit Your Needs:

These conveyors are not made to fit all needs. A lot of manufacturers let you change things to fit the needs of specific uses. Customization means that the conveyor is made to fit the needs of your business. This could mean changing the incline of the conveyor to something steeper than the normal range, adding special coatings to protect against corrosion, or adding extra features like product guides.

Considering Maintenance Requirements:

Because they need to be cared for, incline conveyors need to be repaired often to make sure they last a long time and keep working well. Check to see how easy it is to get to for repair work, and look at features like belt tensioning systems that can help you avoid having to make as many adjustments by hand. If you know what kind of maintenance a conveyor needs, you can plan ahead and keep downtime to a minimum while also making the whole process run more smoothly.

Examining Cost of Ownership:

When you look at the total cost of ownership, you can see a bigger picture. The starting cost of an incline conveyor is important to think about, but the total cost of ownership shows you the bigger picture. The full price depends on things like how much power it needs, how often it needs to be serviced, and how long the conveyor is meant to last. Any conveyor that has a low cost of ownership is likely to be a good long-term buy that fits your budget and will move materials safely and quickly.

Seeking Expert Guidance:

When it comes to incline conveyors, where many factors affect the best choice, it can be very helpful to get professional help. Material handling experts and companies that make conveyor systems can give you information about the newest technologies, best practices, and new trends in the business. By talking to professionals, you can be sure that the choice you make will be well-informed and fit the wants and challenges of your operation.

A custom solution for operational success

It’s not enough to just pick out a piece of equipment when looking for an incline conveyor; you need to make sure that the answer fits perfectly with your complex material handling process. Each part of the selection process is very important. You need to know about the properties of your materials, figure out how much throughput you need, and look at room limitations and safety features.

With the right incline conveyor, the system stops being just a piece of equipment and becomes a useful tool as the needs of the business change. Get the right machine for your business, and it will run more smoothly, save money, and do well in general. It’s important to know exactly what you need before you buy a incline conveyor. As the world of material handling changes all the time, this will help you run your business better, get more done, and keep winning.